Sustainability at Work

Our Responsibility

As the largest marine drayage company in the nation and a global thought leader in the industry, it is incumbent upon us to operate in a manner that protects the environment and enables longevity for all involved in the supply chain - from shippers to end users and beyond. We are proud to be early adopters of alternate energy sources, sustainable equipment and emerging technologies. In fact, our goal is to replace all diesel tractors in California by 2028 with sustainable technologies, far ahead of the mandate of 2035. We believe so much in the power of drayage that we want to practice it in a way that enables it to continue indefinitely.

A Blended Approach to Sustainability

We have a blended approach to deploying Zero Emissions vehicles. Specifically, we have made substantial investments in both electric and hydrogen-powered trucks – both of which have unique benefits and serve a specific role in the supply chain. These units have been deployed in Southern California, where 60% of communities contend with air quality issues daily.

In addition to the hydrogen and electrical zero-emission vehicles, IMC has added 117 diesel tractors with emission reduction technology that all run on biodiesel fuel. This blended approach allows IMC to provide sustainable drayage solutions for a variety of customer needs.

Sustainable Infrastructure

Simply deploying these zero emission vehicle is not enough. To be successful, planning for charging electrical vehicles is crucial. To support the charging of our ZEVs, IMC installed a system of chargers for our electric tractors with internal battery storage. This allows our team to charge the tractors any time, regardless of electrical grid status. The charging stations then replenishes itself when the grid stress is least, reducing our burden on the infrastructure.

IMC SmartStack with FMS

In 2024 IMC Logistics and Fenix Marine Services (FMS) joined forces to operate the supply chain industry’s first fully clean energy SmartStack.

FMS segregated and stacked the containers designated for the IMC SmartStack at their terminal using their hydrogen fuel cell top-pick handler. IMC drivers then picked up and delivered containers using our fleet of zero-emission vehicles. This collaboration highlights the industry’s commitment to reducing carbon emissions while ensuring efficient and sustainable logistics operations.

In addition to achieving environmental objectives, customers also benefit from shorter wait times. “IMC SmartStacks improve the process for shippers, drivers and the industry,” said Mason George, president of National Accounts at IMC. “With this solution, we’re able to offer our customers a sustainable way to evacuate containers from the terminal, while quickly delivering their containers in just two days or less.

As leaders in our field, we're committed to protecting the environment and ensuring a sustainable future for everyone in our supply chain - from shippers to end users.

We’re Carbon Neutral in Compton and Beyond!

IMC has taken an aggressive stance with facility improvement, both in warehouse operations as well as general electrical savings. All IMC facilities in California have been upgraded to both interior and exterior LED lighting to dramatically reduce energy consumption. The IMC transload facility located in Compton has converted to an all-electric forklift model and we also have a Battery Electric Yard Hostler at this site. We’re proud that our Compton facility is powered by 100% Renewable Energy and completely carbon neutral. We are in the process of applying this same technology in other IMC locations.

A History of Sustainability

For more than a decade, we have been part of the SmartWay® Transport Partnership, an innovative collaboration between U.S. Environmental Protection Agency (EPA) and the trucking industry. SmartWay® helps carriers advance supply chain sustainability by measuring, benchmarking and improving freight transportation efficiency. IMC’s west coast region was an early adopter of renewable diesel and has recently been named to the SmartWay® High Performer list. We continue to aim to be a good steward of the environment and we will work to find even more ways to reduce emissions while providing efficient and sustainable supply chain transportation solutions.

A Sustainable Process

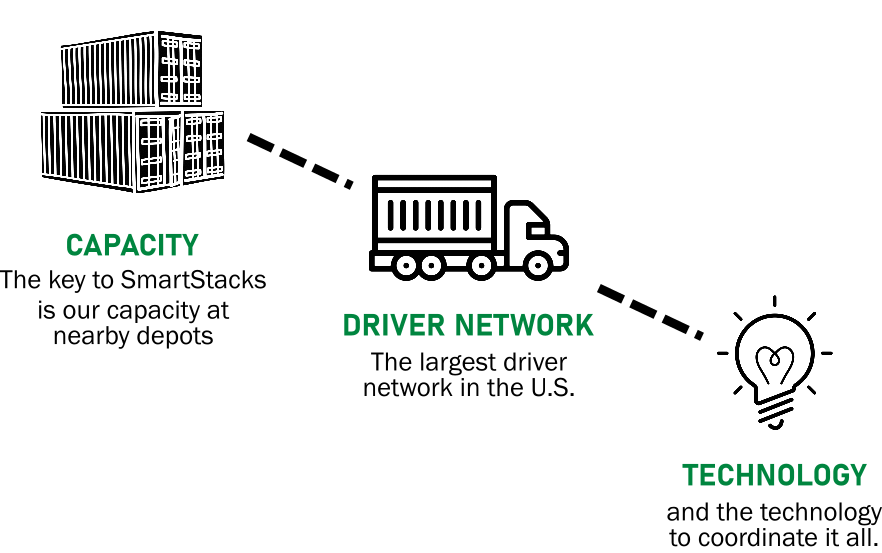

Maximizing sustainability is as much about process as it is about equipment. That’s why we developed SmartStacks, our proprietary version of a “peel pile” that improves port efficiency, decreases dwell time and enhances the cargo experience for shippers, drivers and end users alike. With SmartStacks, the containers of multiple shippers are placed into the same peel pile. Using IMC’s proprietary app, drivers instantly see the container’s destination and can choose to deliver the container to its final destination or instead bring it to a nearby IMC depot. Learn more at www.peelpile.com.

We also maximize the potential of the supply chain through a technique called Matchback. This process allows us to put your cargo into containers that would otherwise travel back to a designation empty. We save customers time and money by matching loads to containers traveling back to the desired location. Learn more HERE.

Leveraging these methodologies, IMC has increased driver productivity, eliminated wasted lifts, and made cargo more accessible to our customers.